Contract Manufacturing in Pharma: What You Need to Know About Outsourced Drug Production

When you take a generic pill, chances are it wasn’t made by the big name on the box. That’s where contract manufacturing, the practice of outsourcing drug production to third-party labs. Also known as CMO (Contract Manufacturing Organization), it’s the hidden engine behind most affordable medications worldwide. Big pharma companies don’t always make their own pills—they hire specialized factories to handle production, packaging, and sometimes even testing. This isn’t cutting corners. It’s how most generic drugs stay cheap, safe, and available. In fact, over 70% of generic drugs sold in the U.S. come from contract manufacturers, mostly overseas.

Why does this matter to you? Because contract manufacturing, the practice of outsourcing drug production to third-party labs. Also known as CMO (Contract Manufacturing Organization), it’s the hidden engine behind most affordable medications worldwide. This isn’t cutting corners. It’s how most generic drugs stay cheap, safe, and available. In fact, over 70% of generic drugs sold in the U.S. come from contract manufacturers, mostly overseas.

Why does this matter to you? Because generic drugs, medications with the same active ingredients as brand-name drugs but sold at lower prices. Also known as non-branded drugs, they rely entirely on contract manufacturers to meet global demand. If the CMO cuts corners on stability testing or fails to follow FDA or WHO standards, you could get a drug that doesn’t work—or worse, one that harms you. That’s why posts here cover stability testing, the process that ensures drugs remain effective and safe until their expiration date. Also known as shelf life validation, it’s a non-negotiable step in contract manufacturing. You’ll also find deep dives into bioequivalence, how regulators prove a generic drug works just like the brand version in your body. Also known as drug absorption comparison, it’s the gold standard for approving generics made by contract labs. And if you’ve ever wondered why your generic pill looks different or causes new side effects after a switch, that’s often tied to how the CMO formulated it—or whether they tested it properly under fed or fasted conditions.

Contract manufacturing isn’t just about cost. It’s about access. Without it, life-saving drugs like abiraterone for prostate cancer or azilsartan for high blood pressure in cancer patients would be too expensive for most people. It’s also how countries with weak local manufacturing get medicines they need. But that system only works if the factories follow the rules. That’s why this collection includes posts on drug production, the end-to-end process of making pharmaceuticals from raw ingredients to finished tablets or injections. Also known as pharmaceutical manufacturing, it’s the backbone of every generic you take. You’ll learn how packaging affects shelf life, why some inhalers and patches need special bioequivalence testing, and what happens when a CMO skips quality checks.

What you’ll find here isn’t theory. It’s real-world insight from people who’ve seen what happens when contract manufacturing works—and when it fails. From nasal sprays to anticoagulants, the posts below show you how to spot the difference between a well-made generic and a risky one. You’ll learn what to ask your pharmacist, how to read between the lines on safety reports, and why the factory behind your medicine matters just as much as the label on the bottle.

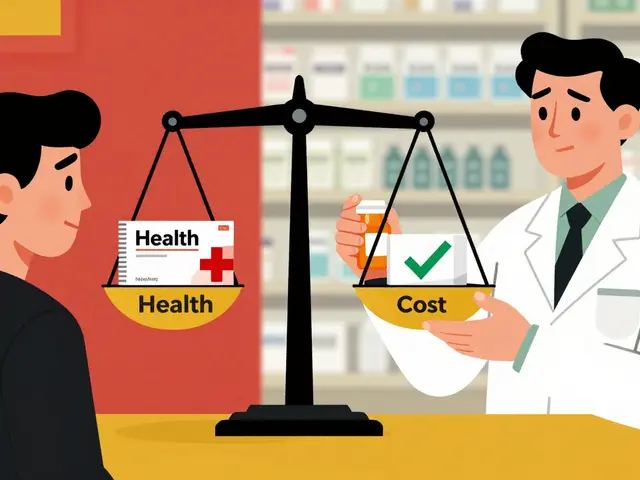

Generic Manufacturer Profitability: Business Models and Sustainability

Generic drugs save billions in healthcare costs, but most manufacturers are losing money. Discover why simple generics are collapsing, how complex drugs and contract manufacturing are reshaping the industry, and what it means for medicine access.